Articles

This article adresses certain obstacles blocking the way for a lead-free transition in the piezo industry.

Read the article: New knowledge of humidity could unlock lead-free piezoelectric ceramics

Written by Astri Bjørnetun Haugen, M.Sc.Eng.Ph.D., Gianni Ferrero, M.Sc.Eng.Ph.D., Malte Aarenstrup Launbjerg. M.Public., and Erling Ringgaard, M.Sc.Eng.Ph.D.

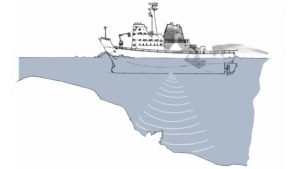

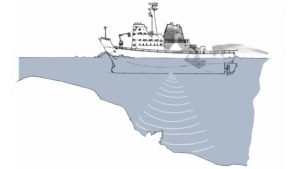

This article explains how various applications utilize piezoelectric components to generate ultrasound.

Read the article here: How is the piezoelectric effect used to generate ultrasound?

Written by Louise Bierregaard Møller, M.Sc.Eng., and Malte Aarenstrup Launbjerg, M.Public.

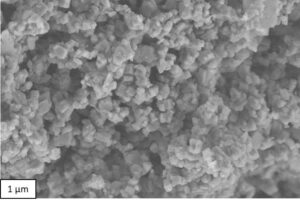

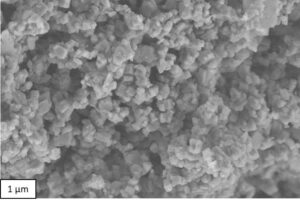

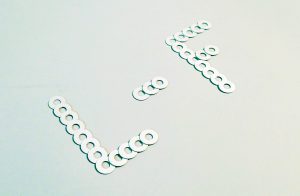

This guide explains the process of manufacturing piezoceramic materials.

Read the guide here: How are piezoelectric ceramics made?

Written by Erling Ringgaard, M.Sc.Eng.Ph.D., and Malte Aarenstrup Launbjerg, M.Public.

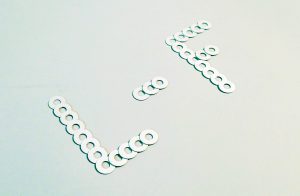

This guide explains the fundamental principles of piezoelectricity and piezoelectric materials.

Read the guide here: What are piezoelectric materials?

Written by Erling Ringgaard, M.Sc.Eng.Ph.D., and Malte Aarenstrup Launbjerg, M.Public.

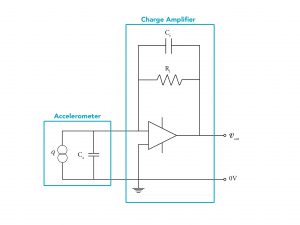

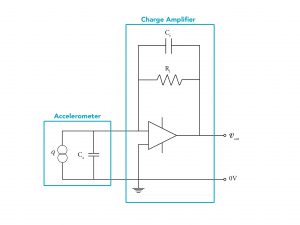

This article examines the various versions of piezoelectric sensors.

Read the article here: How does a piezoelectric sensor work?

Written by Erling Ringgaard, M.Sc.Eng.Ph.D.

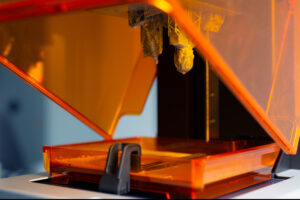

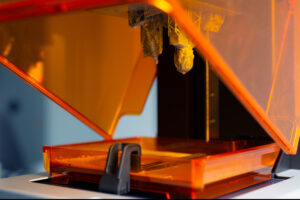

This article explores the potential of 3D printing piezoceramic components.

Read the article here: Printing Piezoceramics

Written by Malte Aarenstrup Launbjerg, M.Public.

CTS Corporation completes acquisition of Ferroperm Piezoceramics.

Read press release here.

This article explains the benefits of switching to lead-free piezoceramics.

Read the article here: Why choose lead-free piezoelectric ceramics?

Written by Rasmus Lou-Møller, Director of Engineering and Business Development.

The article explains which parts a shaker measurement setup consists of and how to build it.

Read the article here: How to build a shaker measurement setup...

Written by Ruichao Xu, M.Sc.Eng.Ph.D.

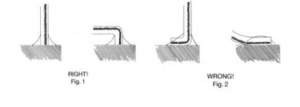

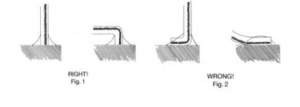

This article explains the most common mistakes you can make when soldering wires to silver electrodes.

Read the article here: How to solder wires to silver electrodes?

Written by Karl Elkjær, M.Sc.Eng.

ENGLISH

ENGLISH