CTS | Ferroperm quality management

60 years of experience in manufacturing the highest quality piezoelectric ceramics.

This is based on purity of raw materials and process control – from the production of material powders to the finished poled and electroded part. We insist that a complete pilot production is completed and approved before each new material batch is released for production. This ensures that mechanical, dielectric and piezoelectric parameters fulfil our strict quality standards.

ISO 9001:2015 certified

The implementation of this system is a continuation of our dedication to use the most modern IT solutions to secure a continuous improvement for our customers and shareholders.

ISO 9001:2015

ISO 14001:2015 certified

The system is fully integrated into the company's web-based quality management system. The implementation is a natural continuation of our dedication to serve our customers with the best piezoelectric products in the world with the best possible consideration to sustainability and long term improvements of our processes

ISO 14001:2015

Ferroperm™ Piezoceramics reproducibility

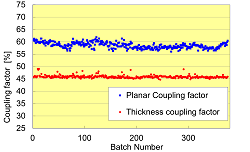

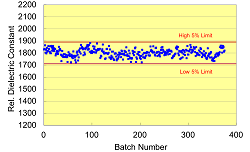

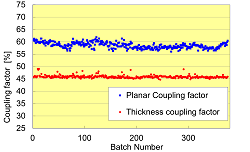

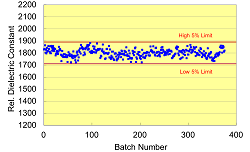

The excellent batch stability of our Ferroperm™ materials is shown below.

The data from each pilot production run is stored in a database. The graphs below are from the production of one of our most common materials (Pz27). They show the very small variation in the free dielectric constant and the coupling factor over >15 years.

Ferroperm™ Piezoceramics for medical devices

Dust free area for medical and miniaturised devices. This new facility has climate control and strict procedures are in place to ensure a clean environment for sensitive products and processes.

ENGLISH

ENGLISH